Frequently Asked Questions

About EPG

Online Course

Leadership

FAQ

What are the benefits of MODAPTS®?

MODAPTS® has numerous benefits for your organization. It will enable you to analyze any manual work. It reduces the time needed to analyze work. It provides you with a work measurement tool that is methods sensitive. And more! Check out founder Ed Eisbrenner’s video: 5 Benefits of MODAPTS® For Your Organization.

What are Eisbrenner Productivity Group’s Qualifications?

In 2016, Ed Eisbrenner was awarded the G.C. Heyde for the worldwide proliferation of the MODAPTS® work measurement system. This prestigious award exemplifies Ed’s commitment to setting reliable work standards.

Ed is also the MODAPTS® Instructor for the Institute of Industrial and Systems Engineers (IISE) and past president of the Work Measurement Division.

Is follow-up support available after I become MODAPTS® certified?

What are MODS?

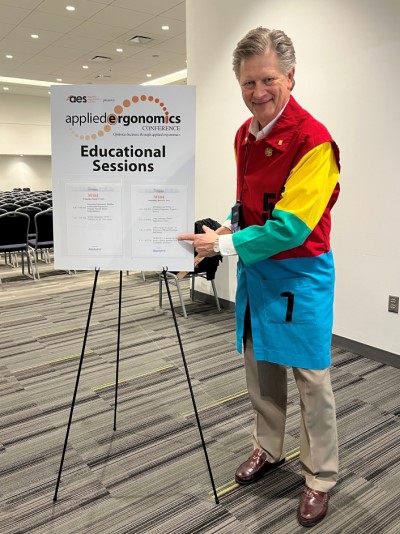

MODAPTS® is a tool used to determine assembly workstation cycle time based on an operator’s elemental body part movements. This eliminates the need for a stopwatch. To help students better understand this concept, Ed Eisbrenner created a jacket to visually demonstrate how the MODs relate to body part movements.

What can my organization expect from MODAPTS®?

Is MODAPTS® a LEAN Tool?

Is the MODAPTS® System Accurate?

Is the MODAPTS® System Consistent?

MODAPTS® has been proven to be quite reliable and consistent with the typical assembly process and workplace.

Do I get a Certificate after the class?

Why am I charged for Shipping for the online course?

Can I take classes in Person?

Yes. Eisbrenner Productivity Group offers on-site and occasionally hosts off-site training in selected cities around the world. When you select on-site training, Ed Eisbrenner will come to your facility and train your team. For off-site training, visit the EVENTS page to see if Ed is coming to an area near you. If you are a professional event coordinator and would like Ed to present an overview of the MODAPTS® system, please contact him directly here.

Eisbrenner Productivity Group also offers virtual classes, which differ from the on-demand online course. The virtual classes are similar to an on-site experience without the associated travel accommodations. To learn more, please click here.

What Languages Is MODAPTS® Available In?

An online Spanish class will be available soon. Watch our website and follow Eisbrenner Productivity Group on social media for availability.

Ed Eisbrenner, CMI

Committed to enhancing operational excellence through improved workforce effectiveness, Ed understands that labor is the single most expensive and controllable manufacturing resource. Ed is passionate about improving the way people perform work tasks and designing ergonomically correct workstations to reduce wasted motions—while also improving production methods-for maximizing efficiency and enhancing any company’s bottom line.

As an experienced change agent who implemented process initiatives that improved quality, productivity, and profitability across manufacturing sites, Ed is a (2) time recipient of Ford Motor Co. Power-train Division’s prestigious Manufacturing Engineering TMM Excellence Award for engine assembly line rebalances.

As a plant ergonomist, Ed was selected by his peers from 24 North American facilities to represent Ford Motor at the IISE’s Annual International Ergonomics Conference and won the first-place award for Innovation in solving an ergonomic concern. In his 26 year career, Ed spent 7 years at the VO Division in Dearborn, Michigan, he mentored directly under George Miko—the founding IMA member, Director and Platinum Instructor of the MODAPTS® system. During that time, Ed completed numerous productivity improvement assignments at 6 of Ford’s North American assembly plants.